Product List

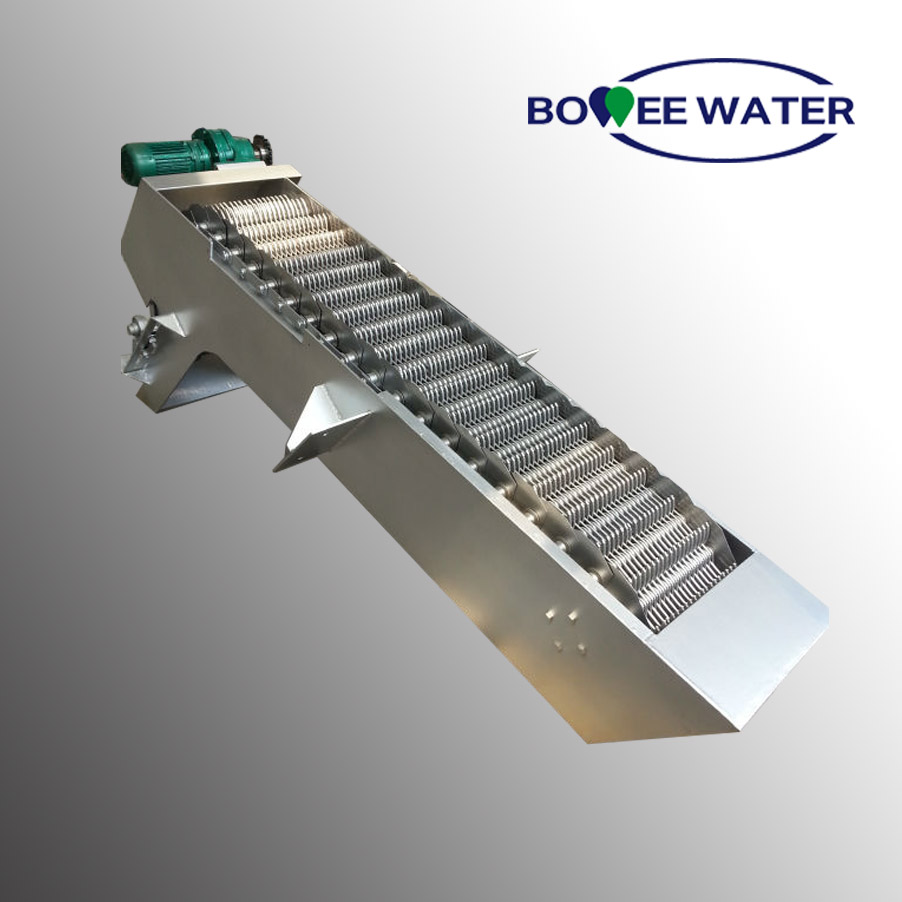

Rotary Rake Screen is an advanced solid-liquid separation device which has been widely used in municipal wastewater treatment plant,pretreatment device for domestic effluents

Specifications:

Dimension: Customized

Material: SS304, SS316 or Customized

Rake Material: SS304,ABS or Customzied

Rake spacing: 1-50mm

Inclined angle: 75°

Motor brand: First-class motor, Nord or SEW is optional

-

Description

Rotary Rake Screen (Also called as rotary solid-liquid separator), is an advanced solid-liquid separation device which has been widely used in municipal wastewater treatment plant,pre-treatment device for domestic effluents, municipal rainwater & sewage pump station,water intake of water supply plant & cooling water of power plant. It can also be used for industrial waste water treatment, such as textile, printing and dyeing, food, fisheries, paper making, brewing, slaughtering and tanning industry. It is regarded as the ideal solid-liquid separation equipment in water treatment field.

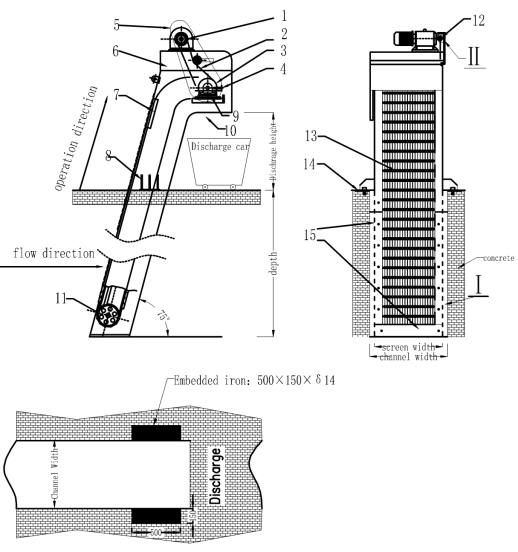

Structure& Working Principle

The rotary screen is installed at the inlet of pump station or water treatment system. It is composed of pedestal, specific plough shaped tines, rake plate, elevator chain and motor reducer units etc. It is assembled into different spacing according to different flow rate. The rake plate, which is fixed in the elevator chain, starts clockwise movement under the drive of the driving device, hooking residue from down to up together with the elevator chain. Under the effect of steering guide and guiding wheel, residue gets discharged by gravity while the rake plate reached the top of screen. The rake tines moved to the bottom of the equipment and starts to work for another round, residue moves continuously.

-

Applications

· domestic effluents

· municipal rainwater

· sewage pump station

· water intake of water supply plant

· cooling water of power plant

· industrial waste water treatment (textile, printing and dyeing, food, fisheries, paper making, brewing, slaughtering and tanning industry)

-

Technical parameters

Model

Parameter

BWRR-500

BWRR-600

BWRR-700

BWRR-800

BWRR-900

BWRR-1000

BWRR-1100

BWRR-1200

BWRR-1300

BWRR-1400

BWRR-1500

Screen width(mm)

500

600

700

800

900

1000

1100

1200

1300

1400

1500

Channel width(mm)

600

700

800

900

1000

1100

1200

1300

1400

1500

1600

Rake spacing(mm)

1-50

Installed angel

60-75°

Channel depth(mm)

800-12000

Discharge height(mm)

600-1200

Rake moving rate

(m/min)

2

Material

SS304,SS316 or customized

-

Advantages

· The driving device is under the drive of cycloidal pin gear speed reducer or helical gear reducer, with low noise, neat structure & stable operation.

· Integrated framework, with good rigidity and convenient installation and maintenance.

· Different spacing of for coarse screens and fine screens.

· Easy to operate. It can be direct or remote controlled.

· Mechanical shearing bolt & over-current protection are set to ensure safe running.

· While the width of equipment over 1500mm, parallel machines are adopted to ensure the integrated strength of equipment.

-

Related Products