Product List

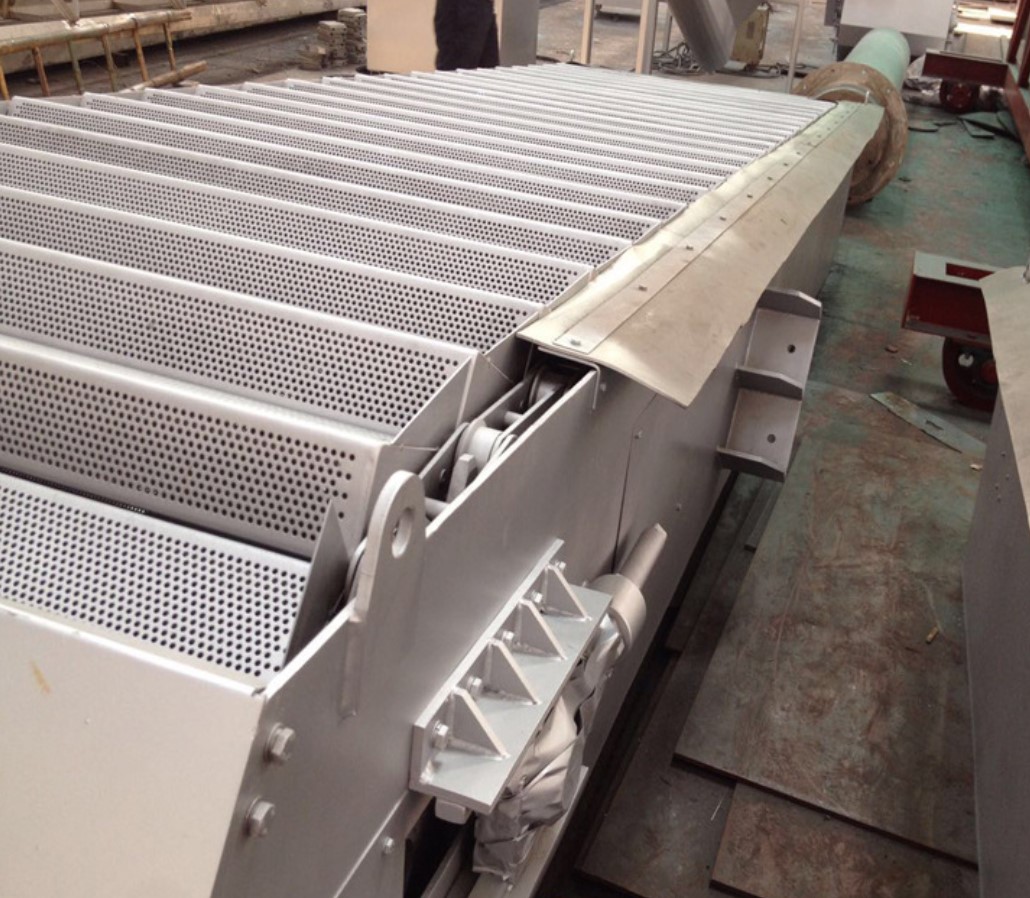

The PERFORATED STEP SCREEN is a kind of advanced solid-liquid separation device in water treatment, which can continuously and automatically remove debris from wastewater for sewage pretreatment, in simple and self-cleansing function.

Specifications:

Dimension: Customized

Material: SS304, SS316 or Customized

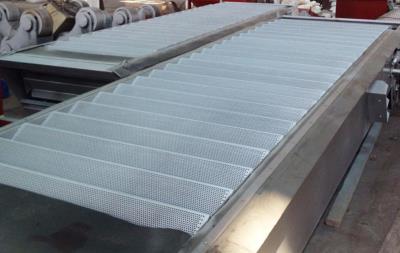

Screen Material: SS304, SS316 or Customized

Hole size: 2-6mm

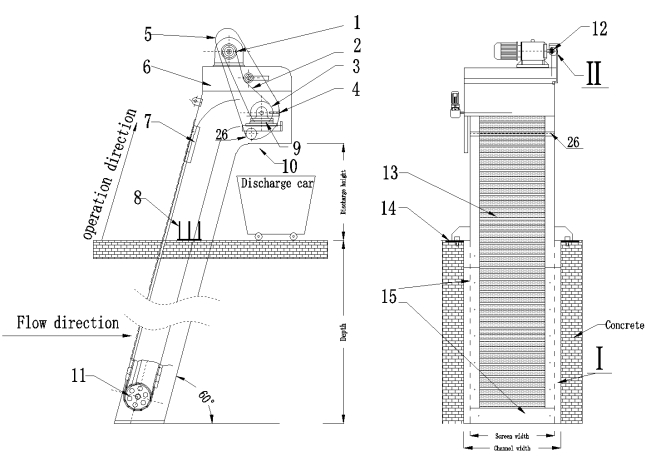

Inclined angle: 60°

Motor brand: First-class motor, Nord or SEW is optional

-

Description

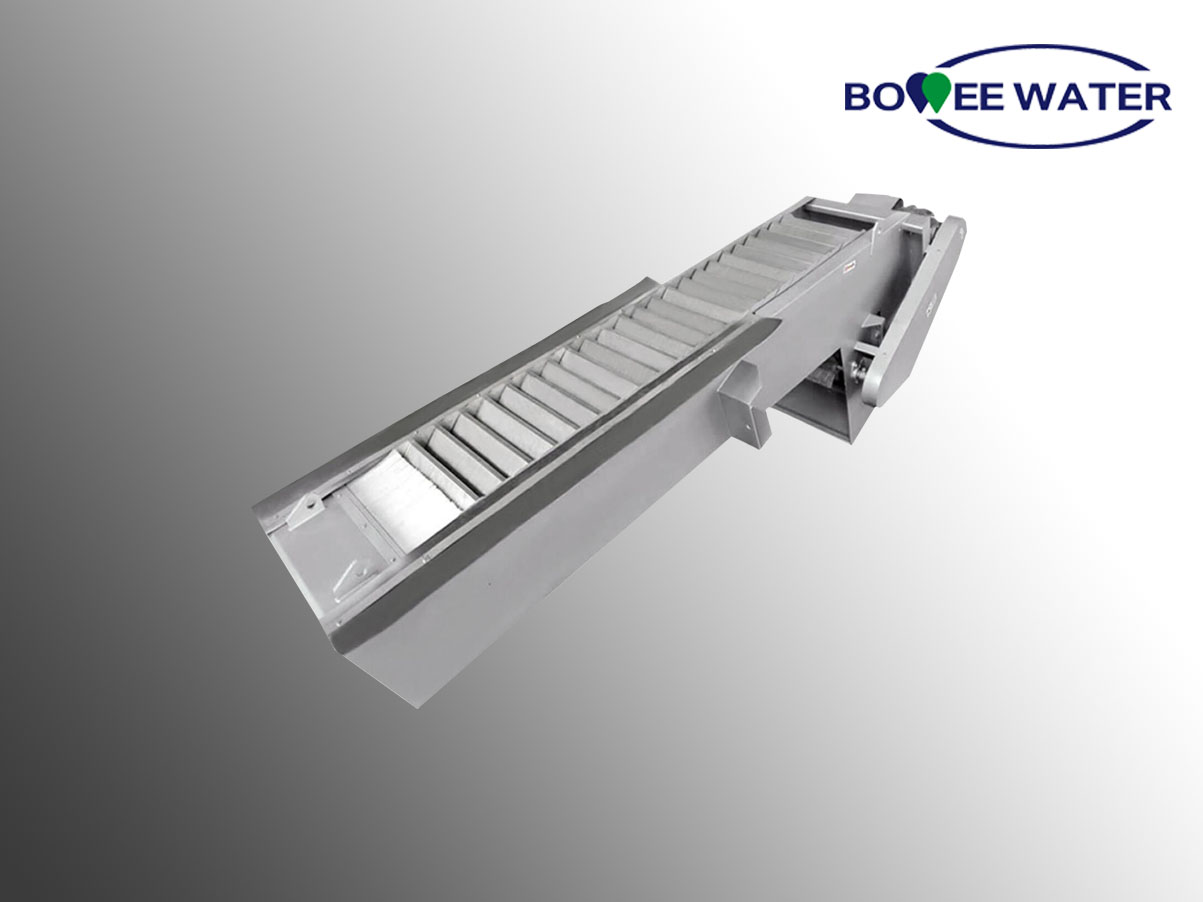

The PERFORATED STEP SCREEN is a kind of advanced solid-liquid separation device in water treatment, which can continuously and automatically remove debris from wastewater for sewage pretreatment, in simple and self-cleansing function. PERFORATED STEP SCREENS are not only highly efficient screens, but at the same time conveyors for gentle lifting and discharging of the screenings. They are suitable for deep channels; they handle high hydraulic and solids loads; and they are easy to operate and maintain.

The PERFORATED STEP SCREEN is installed in channels with an inclination 60° for better removal efficiency. Its discharge height is up to 3.5m above the channel floor. The PERFORATED STEP SCREEN has a linkage system with lubrication-free bearings, defining the exact and parallel movement of the lamellae over their entire length. Use of difficult-to-maintain chains and sprockets and water contamination by oil and grease is thus avoided.

-

Applications

· domestic effluents

· municipal rainwater

· sewage pump station

· Industrial wastewater treatment plant

-

Technical parameters

Screen widths

(mm)

Discharge heights

(mm)

Hole size

(mm)

Inclined angel

(degrees)

Flow rates

(litres/sec)

500 to 2500

1500 to 10000

2-6

60

300 2500

-

Advantages

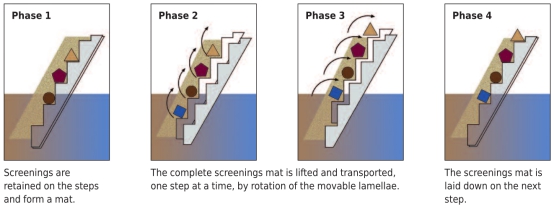

1.Operational Principle: Gentle and complete lifting of screenings and rocks from the channel floor

2.Outstanding Hydraulics: Highest flow / lowest head loss of its class

3.Great Capture Rate: High separation efficiency due to narrow slots, further

4.Spray water or brushes are optional.

5.Odor Control: Fully enclosed screen

6.Maintenance: No need for regular lubrication

7.Reliability: Low susceptibility to jamming by grit, gravel and rocks

8.Overload-protection with rocker arm and proximity switch

9.Durability: Sturdy design, Made of stainless steel

10.Experience: Unsurpassed for more than 10 years; hundreds of installations

-

Related Products