Product List

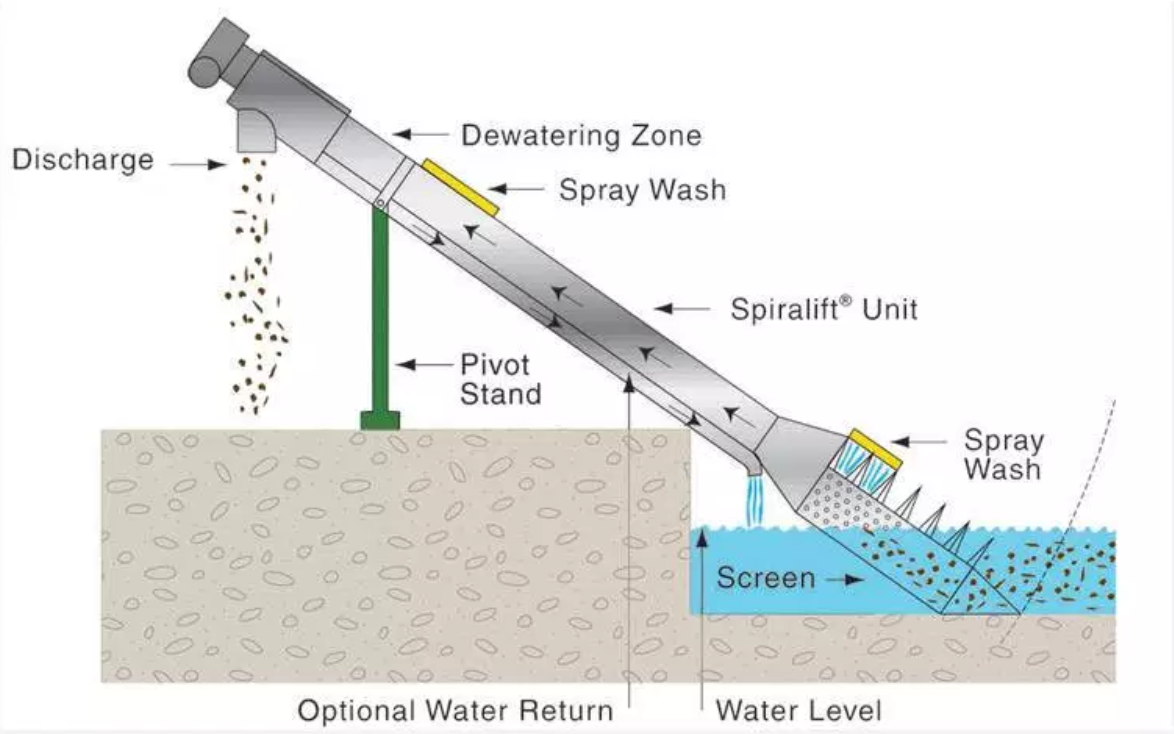

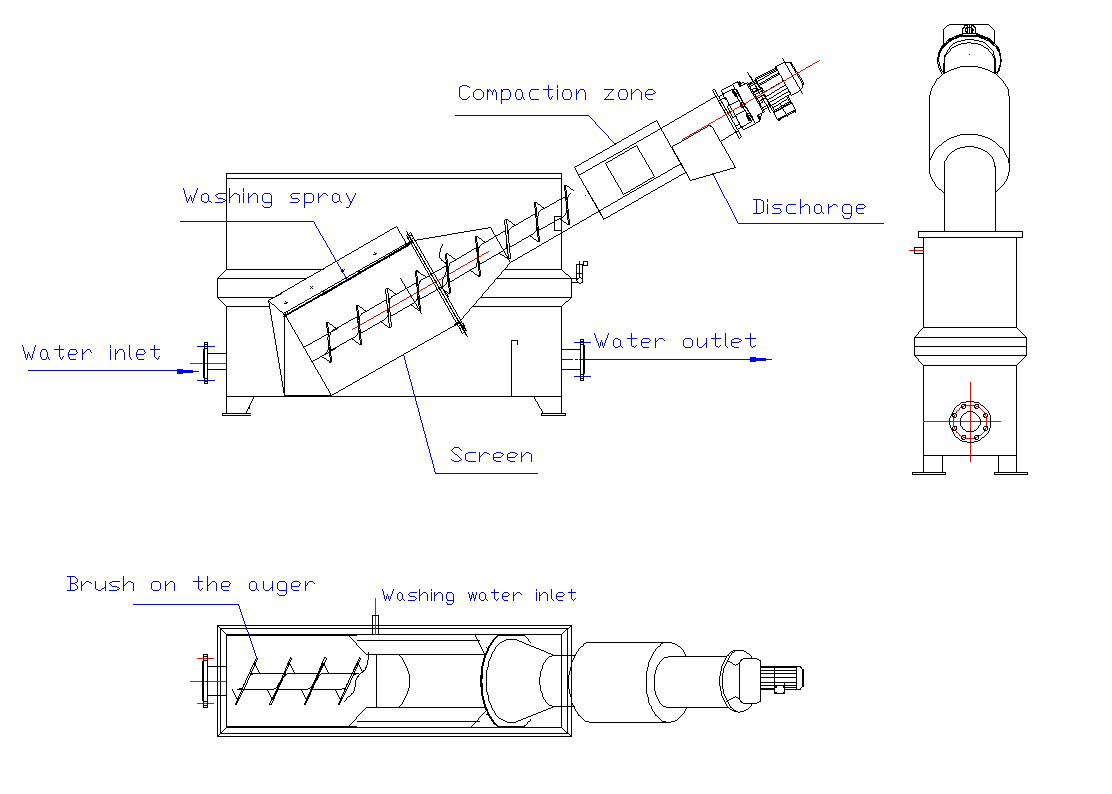

Screw screen effectively separate and convey solids in wastewater and septage applications, installed in-channel or in a self-contained stainless steel tank. Particles are captured on the fine screen basket. As the solids are intensively washed by the high impact spray nozzles, they are swept by the screw auger and transported up the auger. The solids are then discharged at a convenient elevation into a bin, bag, conveyor or separate compactor.

Specifications:

Capacity:10-30m3/h in general

Dimension: Customized

Material: SS304, SS316 or Customized

Opening type: Perforated

Opening size: 1-3mm or customized

Inclined angle: 35°

Motor brand: First-class motor, Nord or SEW is optional

-

Description

Screw screen effectively separate and convey solids in wastewater and septage applications, installed in-channel or in a self-contained stainless steel tank. Particles are captured on the fine screen basket. As the solids are intensively washed by the high impact spray nozzles, they are swept by the screw auger and transported up the auger. The solids are then discharged at a convenient elevation into a bin, bag, conveyor or separate compactor.

The unit is energized on a timed cycle when the upstream flow reaches a predetermined level. An optional compaction zone near the discharge can provide further moisture reduction and compaction of the captured solids.

-

Applications

· WWTP Headworks

· Food Processing and Packaging

· Paper Mills

· Industrial Materials

-

Technical parameters

Material:SS304,SS316 or customized

Screen hole size:1-3mm or customized

Diameter:400mm or customized

Capacity:10-30m3/h in general

-

Advantages

· Screens fine material wastewater that contains hard to detect solids like feather, fur, wool

· Few moving parts ensure easy operation and maintenance

· Screenings that compact inside the does not require additional dewatering equipment

· Screenings washing preserves the organic compounds that further improves the biological treatment process

-

Related Products