Product List

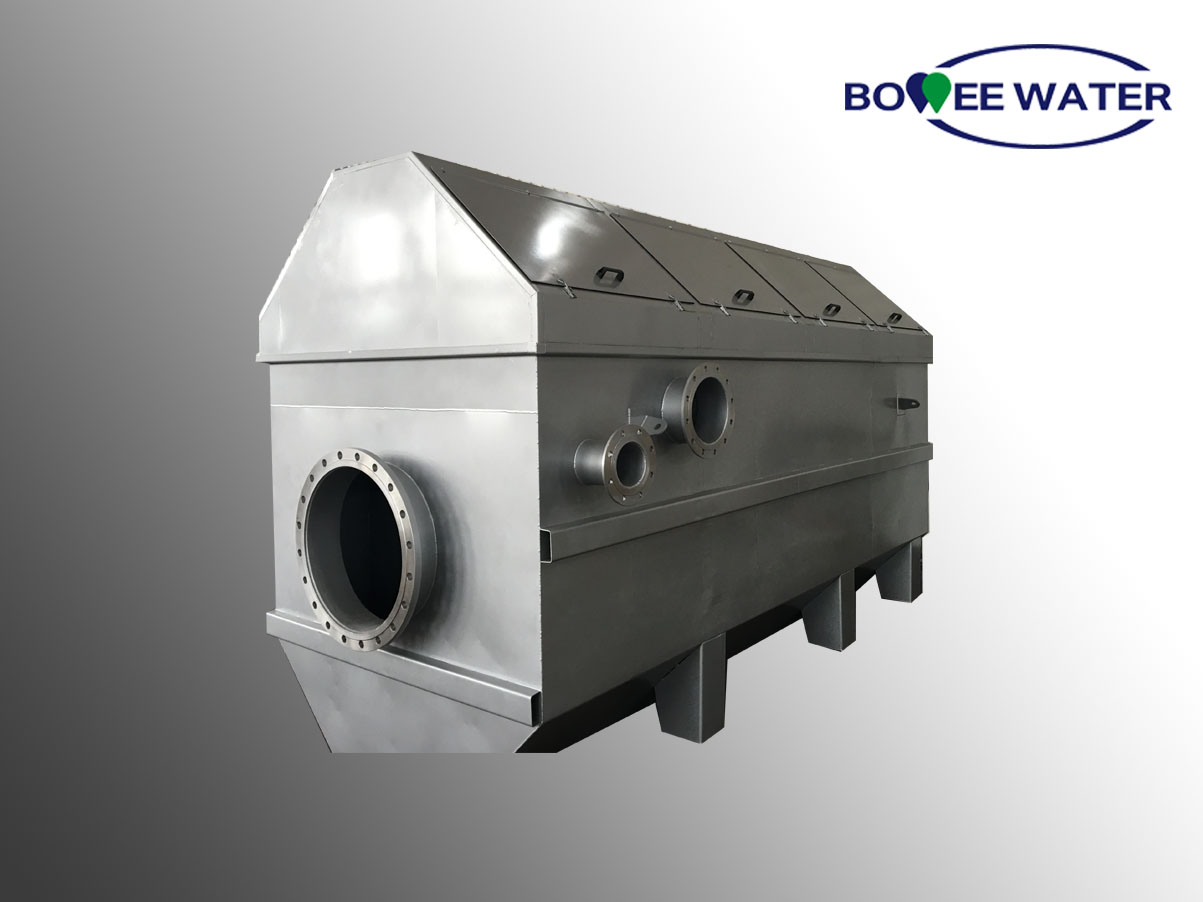

The Drum Precision Filter, internally fed drum screen, employs a rotating drum to provide effective fine screening of a variety of materials with a simple and reliable design,perfect for a wide variety of applications including: Wastewater Treatment, Membrane, Filtration, Fat, Pulp & Paper, Slaughter House and Offal.

Specifications:

Capacity: 5000-30000m3/d

Dimension: Customized

Material: SS304, SS316 or Customized

Opening size: 5-100 micron

Motor brand: First-class motor, Nord or SEW is optional.

-

Description

The Drum Precision Filter, internally fed drum screen, employs a rotating drum to provide effective fine screening of a variety of materials with a simple and reliable design. It is fully constructed in corrosion resistant SS304 or SS316 and employs a cylindrical screen constructed with perforated metal, wedge wire or filter cloth along with a weir system. As the material is fed into the unit’s inlet, it is distributed along the internal screen surfaces. As the drum rotates, the weir moves the solids along the screen length. The liquids are discharged from the unit’s bottom. The solids are conveyed to the unit discharge flange. The Drum Precision Filter is provided in a choice of models with up to 3500-30000m3/d.

The Drum Precision Filter is provided with a choice of screen openings from 5-100 microns perforations. The screen segments are removable from the outside of the unit after simple removal of the exterior stainless steel panel enclosures. The unit is provided with both internal and external high pressure nozzles to keep the screen clear. Each unit is typically supplied with a PLC-based control system housed in a waterproof enclosure. The Drum Precision Filter is perfect for a wide variety of applications including: Wastewater Treatment, Membrane, Filtration, Fat, Pulp & Paper, Slaughter House and Offal.

-

Applications

It could be used in the treatment of industrial wastewater, surface water, reused water, drinking water plant and Municipal Wastewater Treatment Plant.

-

Technical parameters

Item

BWMS-5000

BWMS-10000

BWMS-20000

BWMS-30000

Capacity(m3/d)

5000

10000

20000

30000

Dimension(mm)

2650*1000*2200

2950*1700*2200

3900*1700*2200

5100*1700*2200

Screen diameter(mm)

1000

1290

Screen length(mm)

1200

1200

2400

3600

Mesh size(micron)

5-100

Power(kW)

Gearbox:0.75kW; Backwash pump:2.2kW

Inlet water SS(mg/L)

<40

Outlet water SS(mg/L)

<10

-

Advantages

· Long service life of the filter screen

The service life of Filter screen can be up to 10 years

·Easy to replace the filter screen

Separate meshes can be removed independently without affecting other filters.

· Strong impact load

Equipment can be operated when the inlet SS is not higher than 40mg/L.

·Filtering can run continuously

Backwashing and filtering do not affect each other.

·Small water head loss

Water head loss is less than 750px.

· The discharge water quality is good

Outlet water SS is less than 10mg/L

·Fully automated control

·Small footprint

With the same amount of treated water, the area of precision filtration equipment is much smaller than other filtration equipment.

·Back washing consumes less water

Impurities are not easy to accumulate on the filter, the backwash high-pressure water can remove the impurities easily. The water is taken from the filtrate, and the water consumption is 0.3%, much lower than other similar filters 3%-5%. Reduce the burden of post-processing of backwash wastewater

·Low operating energy consumption

The power consumption is 1/4 of other similar filter screens.

-

Related Products